Sandwich Panel

At Nasir & Sons Engineering Company, we are recognized as one of the leading manufacturers of polyurethane (PU) sandwich panels in Pakistan and beyond. These panels form the foundation of modern cold storage, refrigeration systems, prefabricated buildings, and industrial warehouses. Designed with advanced technology and premium materials, our PU sandwich panels provide an unbeatable combination of thermal insulation, structural strength, and long-term durability.

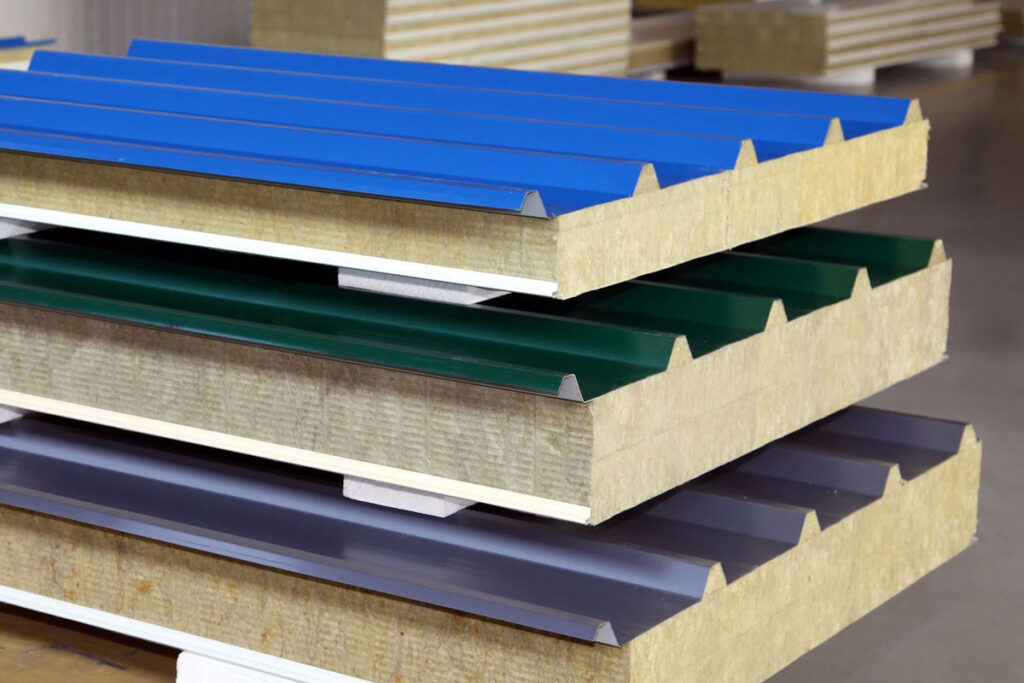

Each panel is manufactured through a state-of-the-art process in which polyurethane foam is injected under high pressure between two layers of pre-coated galvanized steel or stainless steel sheets. This results in a panel that is lightweight, corrosion-resistant, and highly effective in minimizing heat transfer. Compared to traditional construction methods such as concrete or brick, PU panels are thinner and lighter yet deliver superior insulation, allowing businesses to save space and significantly reduce energy costs.

Our sandwich panels are available in multiple thickness options — 50mm, 75mm, 100mm, 125mm, 150mm, and up to 200mm — to suit a wide variety of applications. With a maximum panel length of 10.6 meters, they can cover large areas seamlessly, reducing the need for joints and improving efficiency. The density of the polyurethane foam ranges from 40–45 kg/m³, ensuring consistent performance even in extreme conditions.

In addition to their insulation performance, our PU sandwich panels are designed with cam-lock joint systems and odorless silicone sealants that ensure an airtight fit, preventing any loss of cooling and enhancing the longevity of refrigeration systems. The panels are also available in a wide variety of surface finishes including color-coated galvanized steel plates, embossed aluminum, and stainless steel sheets, offering durability with an aesthetic appeal suitable for both industrial and commercial projects.

Key Features of Our Sandwich Panels

-

Superior thermal insulation with low conductivity (0.017–0.018 Kcal/m·h·°C).

-

Lightweight and strong, reducing structural load while maximizing usable space.

-

Available in multiple thicknesses (50mm–200mm) and lengths up to 10.6m.

-

Corrosion-resistant finishes: galvanized steel, embossed aluminum, or stainless steel.

-

Cam-lock joints and silicone sealing for airtight, secure installation.

-

Long-lasting durability with 10-year warranty on insulated panels.

-

Easy to install, dismantle, and relocate when required.

Applications

PU sandwich panels from Nasir & Sons are widely used in:

-

Cold rooms and blast freezers

-

Prefabricated houses and warehouses

-

Pharmaceutical clean rooms and laboratories

-

Supermarkets, processing plants, and logistics centers

-

Industrial and commercial buildings requiring insulation

Why Choose Nasir & Sons Panels?

-

Energy Savings: Reduce cooling and heating costs with world-class insulation.

-

Flexibility: Wide range of designs, thicknesses, and finishes to suit every project.

-

Hygiene & Safety: Easy to clean surfaces, non-toxic sealing, and moisture resistance.

-

Long-Term Value: Backed by durability, warranties, and 24/7 after-sales support.

By using Nasir & Sons PU Sandwich Panels, businesses gain a reliable, high-performance building solution that combines efficiency, sustainability, and structural integrity. Whether for cold storage, prefab buildings, or industrial applications, our panels deliver the ultimate balance of technology, quality, and affordability.

Contact now